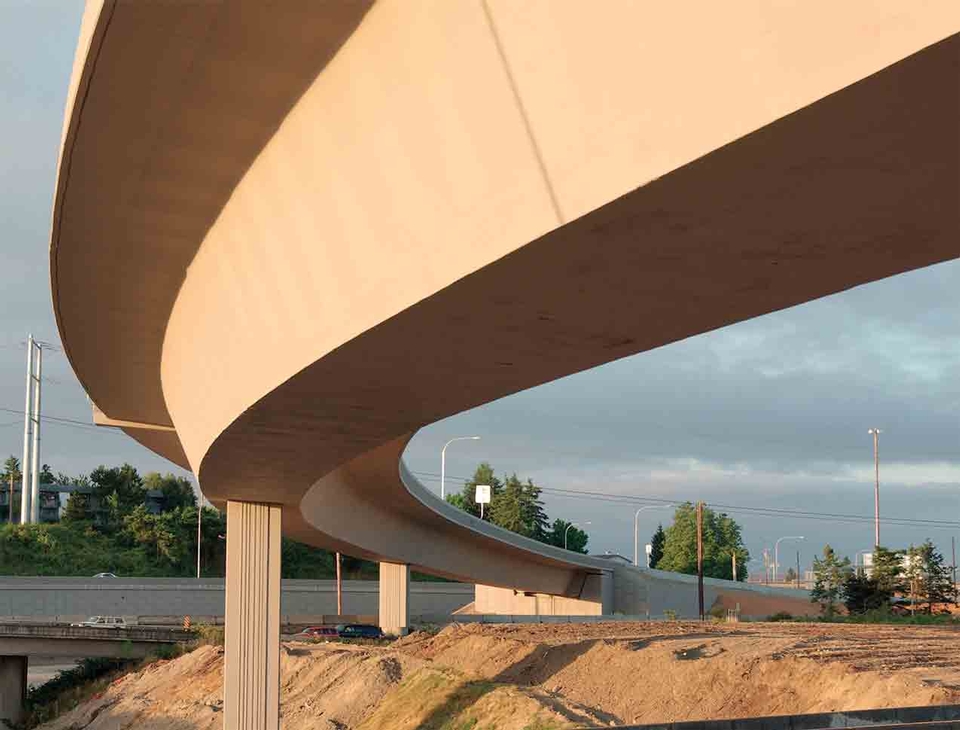

SW Line Bridge Nalley Valley Interchange – Tacoma, Washington

The Nalley Valley Interchange, in Tacoma, Washington, is undergoing a major reconstruction of the original interchange opened to traffic in 1971. It is being re-designed and reconstructed in several design bid-build packages that will extend over several years. The westbound viaduct is the “jumping off point” for motorists on I-5 heading west to the Tacoma Narrows Bridge and the Olympic Peninsula on State Route 16. Because this SW Line flyover was first bid as a steel box girder bridge and ended up as the Washington State Department of Transportation’s (WSDOT) first precast concrete segmental bridge, the project proved to be a “jumping on point” for WSDOT as well. Volatile steel prices at bid time in October 2008 were the primary incentive for the contractor to consider redesigning the two steel bridges on the project. However, this “first” use of a precast segmental bridge would not have happened without the contractor’s and owner’s desire to advance segmental precast concrete technology in the state.

Innovation of Design and/or Construction

Redesigns can be challenging simply because the bulk of the engineering is performed post-bid. The larger challenge on this project was designing a concrete bridge that could be supported on a pier column that was not only designed for a steel bridge, but already had been built in a previous contract.

For this to happen required some amount of luck. First, the end span adjacent to the constructed pier was the shortest span on the bridge and there was some reserve capacity in the original design. Second, the key to the design was making an integral connection to the superstructure in lieu of bearings used in the original steel design. Using an integral connection significantly reduces the moment arm for longitudinal seismic loads.

The four-span bridge is 1,061 feet long with span lengths of 225, 295, 295, and 246 feet. It has a 43-foot wide roadway, providing two travel lanes and shoulders. The superstructure consists of a single-cell box with a constant depth of 12 feet. The webs are typically 15 inches thick but increase to 20 inches at the piers. Similarly, the bottom slab transitions from 9 inches to 24 inches at the piers.

To minimize weight and satisfy shear demands in a relatively shallow structure required the introduction of inclined post-tensioning tendons. To increase ductility and continuity for seismic demands, the inclined tendons are located in the webs and anchored at each pier. A typical cantilever consists of 15 segments in all. The first five segments from the pier are 8 feet long with thickened webs and bottom slab as well as draped web tendons. The remainder of the segments are 10 feet long and, a portion of these, have bottom slab anchorage blisters for the continuity post-tensioning.

Segments were produced using the long-line casting method. This involved beginning at the pier segment and match casting segments toward the middle of the span. Concrete slabs were constructed on which to cast the segments. These slabs defined the profile geometry. A polyethylene sheet and plywood on top of the slab provided a slip plane to separate segments prior to erection. The movable formwork was bolted to the slab at each segment joint. The long-line casting method allowed the segments to be cast and stored in one place and eliminated the need for large handling equipment in the casting yard until segments were loaded for shipment to the bridge.

Match-casting the cantilever segments with the precast pier segments eliminated the need for a cast-in-place concrete joint and associated starter segment brackets during erection. Making the pier segment integral with the pier column was achieved by blocking out the webs and the bottom and top slabs to allow placement of the diaphragm reinforcement. The precast “shell” was erected by lowering it down over the pier column onto supporting brackets. There it could be aligned and made integral by the cast-in-place concrete diaphragm pour.

Cost Competitiveness

Some say that precast concrete segmental construction is considered to be cost effective for projects having 300 or more segments. While this structure only contained 112 segments, its success can be attributed to the economic alternatives that precast concrete offers and the ability to adapt these designs to suit difficult urban settings. And as this project illustrates, innovation and cooperation between owners and contractors can yield successful alternatives for the most difficult projects.

Minimization of Construction Impact on the Traveling Public

Most of the precast segments were erected using balanced cantilever methods, allowing the contractor to limit lane closures and minimize falsework.

Jury Comments

This first precast segmental bridge project was trend setting for the State of Washington and led to a new construction method for the owner. The owner and contractor worked together to advance precast segmental construction to overcome difficult constraints, resulting in a project that was cost effective while minimizing impact to the traveling public.

2011 ASBI Bridge Award of Excellence

Category: Rural Bridges and Viaducts

State:

Washington

Owner:

Washington State Department of Transportation

Owner’s Engineers:

Washington State Department of Transportation

Designer:

McNary Bergeron & Associates with Campbell Construction Engineering

Contractor:

Guy F. Atkinson Construction, LLC

Construction Engineering Services:

McNary Bergeron & Associates

Constructability Review/Estimating Services:

Guy F. Atkinson Construction, LLC

Construction Engineering Inspection:

Guy F. Atkinson Construction, LLC and Washington State Department of Transportation

Precast Producer:

Guy F. Atkinson Construction, LLC

Formwork for Precast Segments:

Aluma Systems

Erection Equipment:

Sicklesteel Cranes, Inc. (Crane Erection), Ness, Van Dyke Trucking (Segment Delivery)

Post-Tensioning Materials:

Schwager Davis, Inc.

Bearings:

The D.S. Brown Company

Expansion Joints:

The D.S. Brown Company

Epoxy Supplier:

Mason Supply (for Euclid Chemical)

Prepackaged Grout:

US Spec

Rebar Furnish/Install:

Apex Steel, Inc.